Published:

Readtime: 5 min

Every product is carefully selected by our editors and experts. If you buy from a link, we may earn a commission. Learn more. For more information on how we test products, click here.

The high-performance arm of Japanese watchmaker Seiko, Grand Seiko has been challenging norms and raising the bar on accuracy since 1960. Those themes certainly continue with recent models such as the new SBGC253 Spring Drive Chronograph GMT, a stunning timepiece that won us over more or less immediately. Iconic at first glance, the lion-baring chronograph is no less impressive under the skin. That’s where one finds a remarkably precise Spring Drive movement, which was invented by Grand Seiko themselves back in 1998. Here’s a closer look at the historic innovation.

RELATED: We’ll Say It, Grand Seiko’s New Chronograph GMT is Worth the $17,000 Price Tag

An Invention 20 Years in the Making

Most innovations are inspired by a vision and the Spring Drive movement is no exception. The keeper of that vision was Yoshikazu Akahane, an engineer at Suwa Seikosha (now Seiko Epson) in the 1970s. Already the driving force behind a game-changing movement called “twin quartz,” Akahane set his sights on a new technological feat: an “everlasting” watch that would run on a mainspring yet deliver the same one-second-a-day precision as its electronic counterparts.

Not one to let a good dream go to waste, Akahane filed a patent for the “development of an electronically regulated mechanical watch that is powered by a spring” as early as 1978. Momentum was slow if not stagnant until an engineer named Osamu Takahashi joined the project in 1993. Drawing from a background in fluid dynamics, Takahashi created a unique mechanism that used silicon oil and a hairspring to engender the sweeping movement of the seconds hand.

The Power Problem

Takahashi’s mechanism was a major step forward, but it required too much power to work on a functional basis. The entire project was shelved as a result, though both Akahane and Takahashi never gave up on what was now their shared vision of an “everlasting watch,” which would bridge the gap between mechanical artistry and quartz-powered precision.

Enter engineer Kunio Koike, who joined the team in 1997 and became similarly determined to make Akahane’s dream a reality. He and Takahashi (who was now the team leader) pored over the nuances of electricity and circuit design on a fundamental level. They soon arrived at a potential solution to the power issue: what if they used a voltage amplifier circuit so that a quartz crystal and an integrated circuit (IC) could function on a small amount of electricity?

Koike and Takahashi’s solution represented yet another step forward, but the finish line was still nowhere in sight. There was still the significant hurdle of activating quartz crystal (a fixture in battery-powered watches) through the power generated by a mechanical movement. In order for this to happen, power generation efficiency needed to increase while power consumption of the IC needed to decrease.

Meanwhile, original dreamer Akahane was now Grand Seiko’s Chief Operating Officer of the Watch Operations Divison. Between his position of power and Koike and Takahashi’s innovations, the “everlasting watch” project went from obscurity to priority. All hands were officially on deck!

Two Horological Worlds Collide

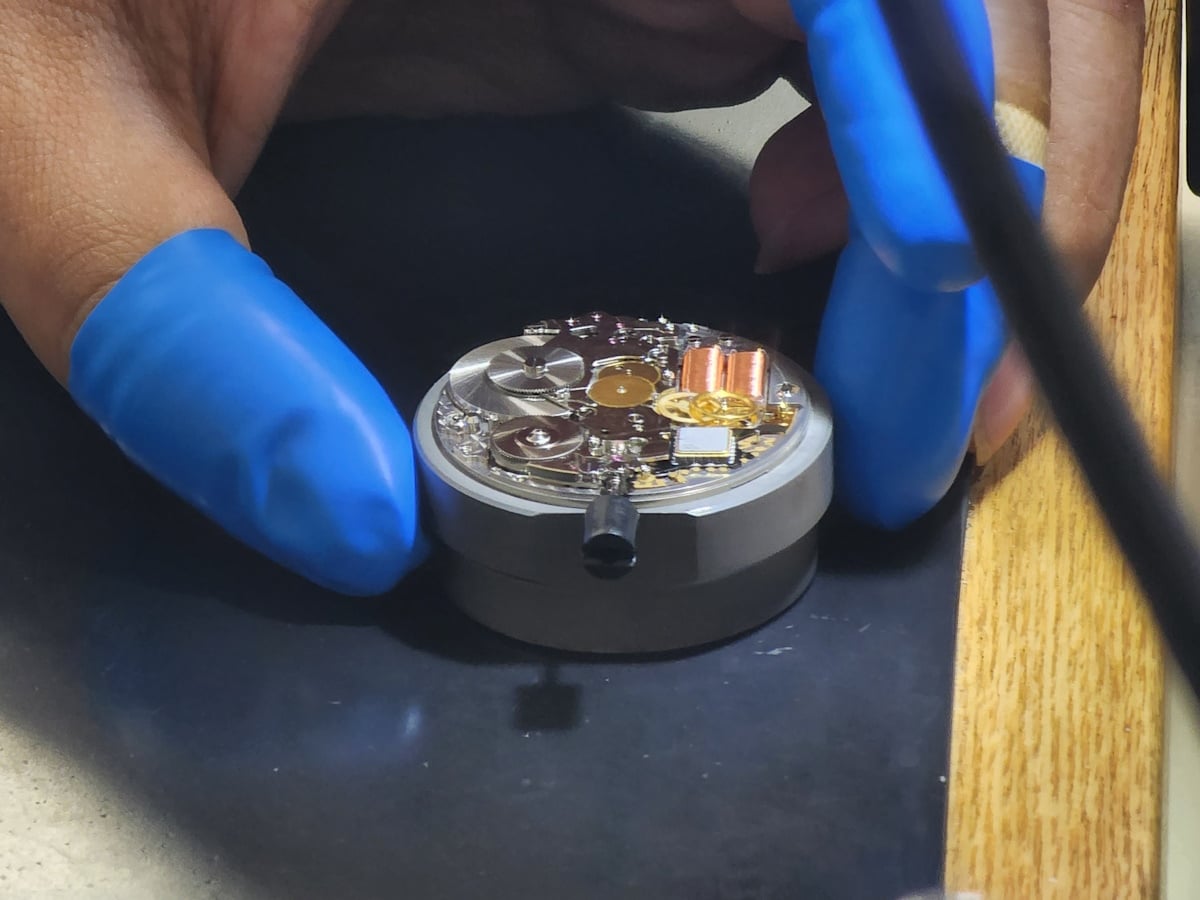

To surmount the latest power issue, Koike and his team drew upon Akahane’s previous efforts as well as the company’s long history of innovation and technological expertise. Their research and development led to the invention of a new low-voltage IC, which was created exclusively for the “everlasting watch.” A prototype was put into a watch for the first time in December of 1997. To the amazement of all those involved, it actually worked (fun fact: the prototype went missing and was later found in Akahane’s desk drawer).

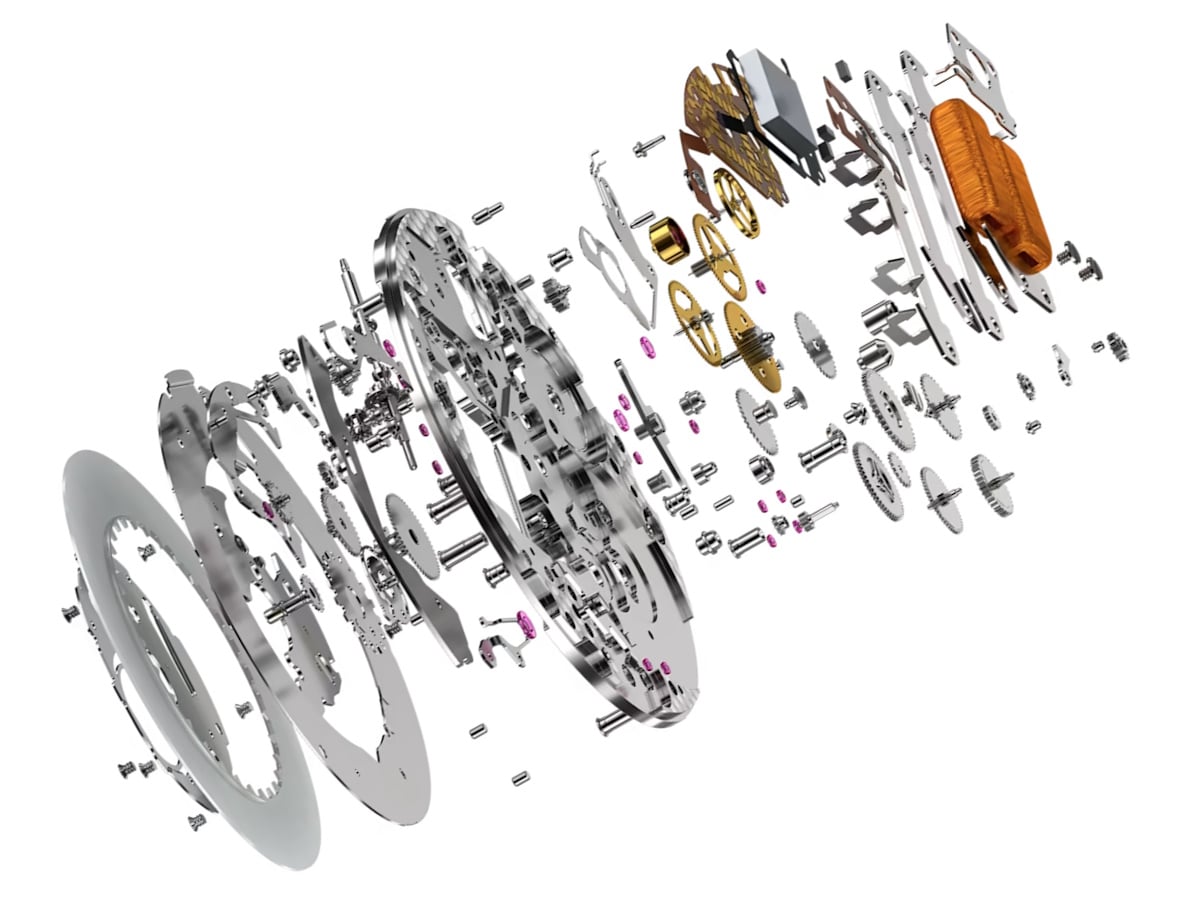

At long last, the dream of a Spring Drive movement had become a reality. It worked by using three unique types of energy. First, there’s the mechanical power generated by the motion of the wearer’s wrist and then stored in the mainspring (which drives the gears). Through electromagnetic induction, some of the mechanical energy is converted into electrical energy, which powers a circuit with a quartz crystal oscillator inside it. The oscillator’s precise time signal then regulates an electronic brake so as to control the revolution speed of each hand on the display.

A New Frontier

After two decades, countless hours, and 600 prototypes, the first hand-winding Spring Drive watch was released in 1999. Five years later, Grand Seiko introduced the first automatic winding Spring Drive watch, which ran on Caliber 9R65 with a power reserve of 72 hours and an accuracy rate of one second per day. In lieu of ticking, its second hand glided silently across the dial face as if to manifest the ever-flowing essence of time itself. And so a revolution was born.

Where there was once a choice between mechanical and quartz-powered horology, Grand Seiko bridged the gap between these respective options and kicked open a new door in the world of watchmaking at large. The uber-precise movement continues to power a number of their best releases, including the new SBGC253 Spring Drive Chronograph GMT. As it turns out, some dreams do come true.

Spring Drive Movement Summary

| Attribute | Description |

|---|---|

| Technology Name | Spring Drive Movement |

| Invention Year | 1977 |

| First Introduced in Market | 1999 |

| Invented By | Seiko |

| Technology Type | Mechanical watch movement with quartz regulation |

| Energy Source | Mainspring |

| Regulation Method | Tri-synchro regulator replaces the traditional escapement |

| Accuracy | +/- 1 second per day or +/- 15 seconds per month on average |

| Unique Feature | Continuous, sweeping second hand (no ticking) |

| Key Models | Grand Seiko Spring Drive, Prospex Spring Drive, Credor Spring Drive |

| Benefits | High accuracy of quartz with the smooth movement of mechanical, long power reserve, no battery needed |

| Popular For | Luxury watches, high-precision timepieces |

Comments

We love hearing from you. or to leave a comment.