Forty years ago, British entrepreneur Sir James Dyson redefined the home-cleaning industry. Now, his son is hoping to do the same for audio.

Five thousand, one hundred and twenty-six. To most of us, myself included, that number appears entirely inconsequential, but to the strangely dedicated team of engineers, designers, and visionaries at technology company Dyson, it is everything. The driving force behind 40 years of industry-leading innovation, the figure is Dyson’s most important metric, but it isn’t a sales target or growth goal. It’s not even a product count. In reality, 5,126 represents founder Sir James Dyson’s staggering tally of failures.

It is a warm afternoon in 1978. In a small English village not far from the Cotswolds, James Dyson, then a little-known industrial designer and product engineer, is powder-coating the metal frames of his magnum opus; the Ballbarrow. Conceived four years earlier, Dyson’s pneumatic ball-driven wheelbarrow has the potential to revolutionise the commercial building industry, making him a household name in the process. For the time being, however, the invention is getting on his last nerves.

Despite his best efforts to contain the mess, the calico cloth behind his makeshift artwork is being drenched in powder, causing the paint to set and clog unfavourably. With each spray of the application gun, Dyson grows increasingly frustrated. ‘There has to be a better way,’ he thinks to himself. Suddenly, inspiration strikes.

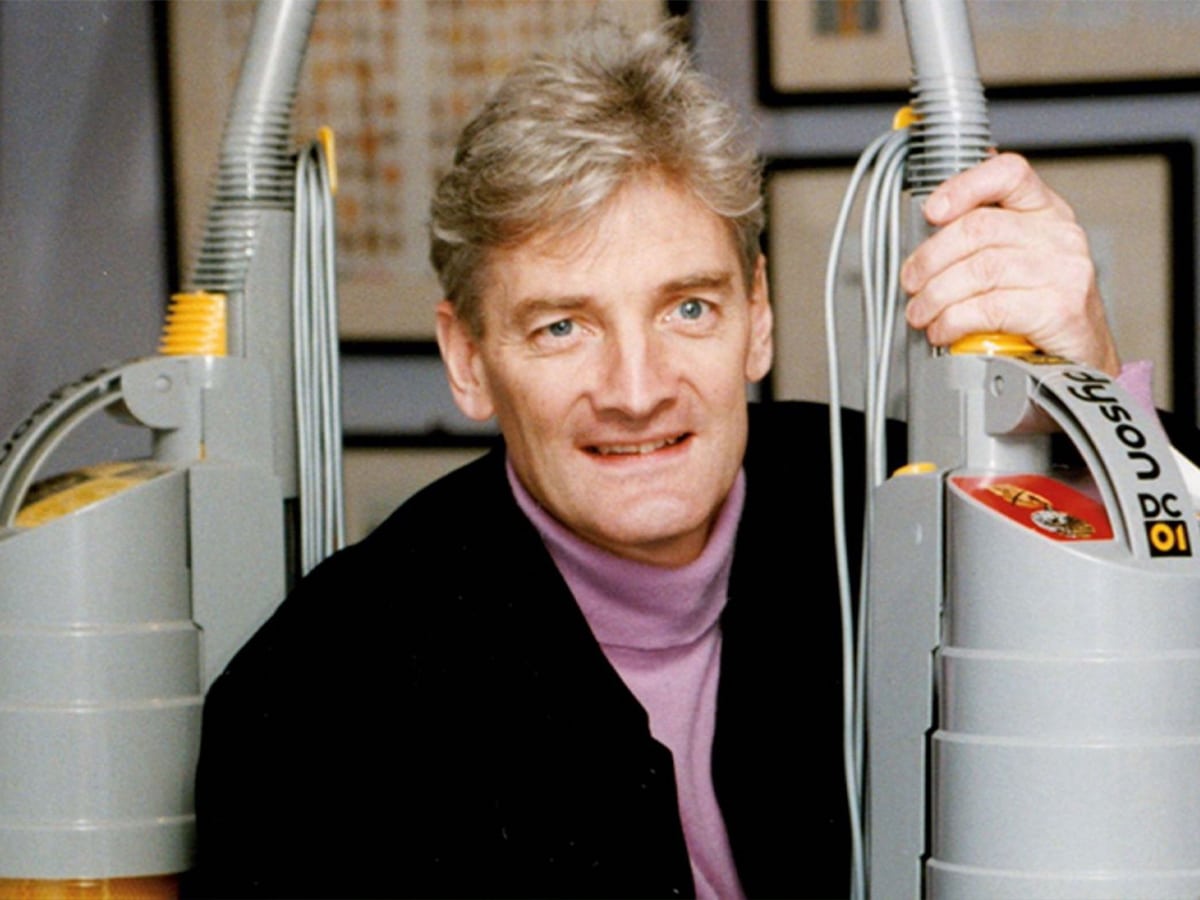

Recalling an industrial cyclone he’d seen at a local timber mill, Dyson throws down the powder gun and picks up the pencil. His plan; design a 25-foot cyclonic structure to suck the waste powder away and prevent potential obstructions. This was, as he would later describe, “a form of filter that never clogged”. Five years, tens of thousands of dollars and a whopping 5,126 failed attempts later, the world’s first cyclonic vacuum cleaner was born.

For Sir James Dyson, now one of the world’s leading technology entrepreneurs and Britain’s richest man, success has been defined by failure. His story is not unique. Like so many inspiring inventors, Dyson understood that failure is not a barrier to success, but rather an important stepping stone in its eventual capture. As he explained in his 2021 memoir, Invention: A Life, giving up was never an option. “The time to push hard is when you’re hurting like crazy and you want to give up, because success is often just around the corner.”

“Enjoy failure and learn from it. You never learn from success.”

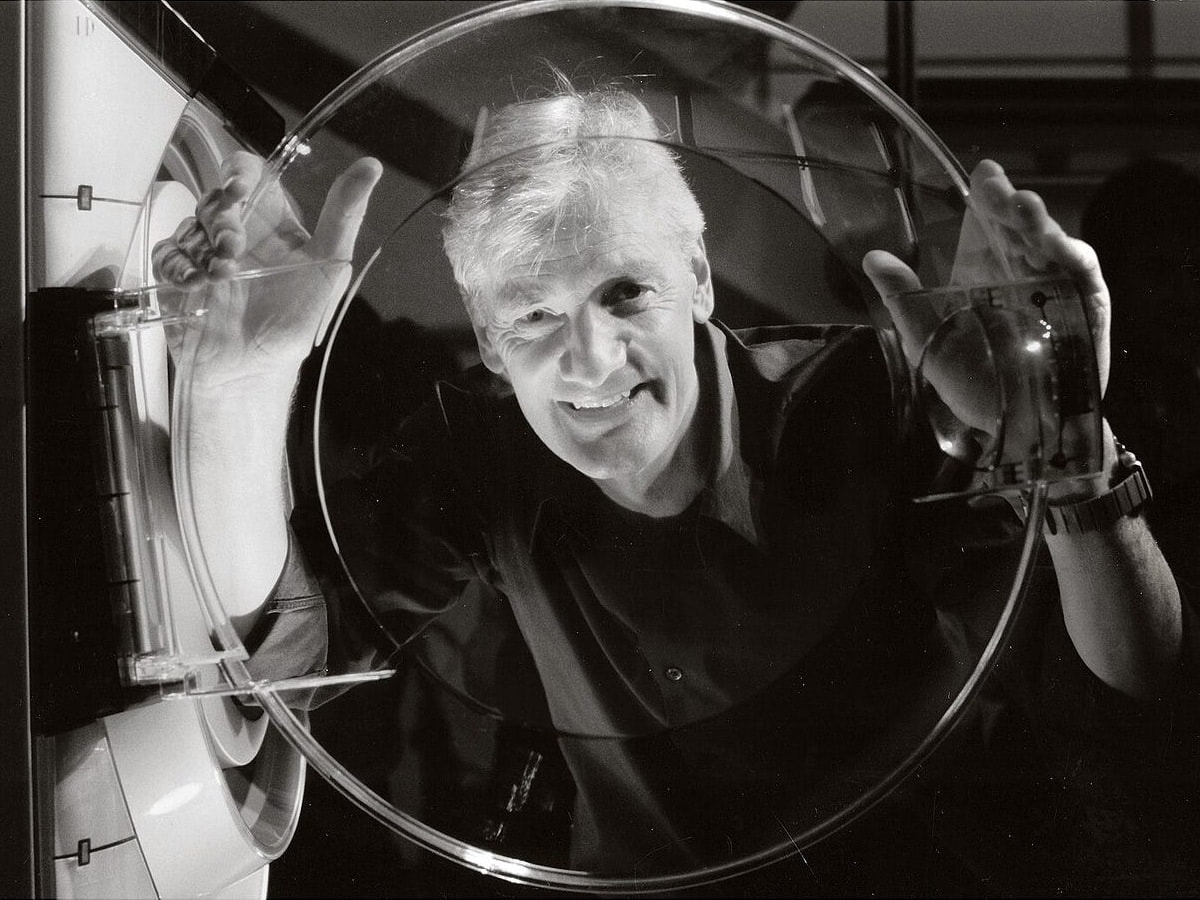

Dyson’s ability to identify an issue and work at unravelling it, often to the point of obsession, is precisely what made his namesake company a success. It’s part of the reason you’ll find the mantra ‘We solve the problems that others ignore’ plastered across every wall and door frame at the company’s futuristic Malmesbury headquarters. That lesson that has been learned the hard way, and not simply by Sir James Dyson himself.

In 2023, under the guidance of Dyson’s son and chief engineer, Jake Dyson, the brand announced a somewhat unexpected foray into the world of audio. The Dyson Zone, the brand’s first-ever audio product, was introduced to great fanfare, albeit with a touch of bafflement. The headphones, while sleek and undeniably ‘Dyson’, doubled as a wearable air purifier, designed to combat growing public concerns over air pollution. Released in the wake of a global pandemic, Zone really should have dominated the market, but it failed to make a lasting impression.

“Certainly, the Zone was completely radical. No one’s ever done that before,” Jake Dyson tells me. “We have to sort of trust our judgment of what we’re doing and have conviction always, but yes, nothing’s a given. Especially as you’re a relatively new kid on the block when it comes to audio playback as well.”

As Dyson, a remarkable engineer and problem solver himself explains, the Zone might not have had the mass appeal that the brand was hoping for but it did provide the ideal ground-floor entry point to the industry. As he puts it, being an industry unknown isn’t always a disadvantage; rather, it allows you to look at things through a new lens.

“I think that’s quite exciting to be a new kid on the block. There are a lot of established brands but I wouldn’t say there’s a lot of movement going on there, necessarily,” he says. “(With Zone) It’s still part of the audio range, but as a purifier, so you must consider it a portable purifier. Most importantly, it gave us a base point for a wonderful product to enter the audio market.”

Ironically, Zone’s introduction was oddly reminiscent of the original Dyson vacuum cleaner. When James Dyson’s cyclonic prototype was first conceived, the vacuum cleaner bag market was worth over $500 million in Europe alone. Content with the existing formula, the industry decried innovation and James’ designs were rejected by all major vacuum manufacturers. Undeterred, the entrepreneur persevered and went at it alone, mass-producing the DC01 in 1983.

With that story of resilience underpinning the entire company’s success, it’s no surprise that Dyson is taking a second crack at the audio game. It has, as you would expect, learned from its mistakes. In July, the brand unveiled OnTrac, its first-ever over-ear audio-only headphones. It’s a mouthful to say, but as Jake Dyson explains, OnTrac is worth every syllable.

“We’re always really excited when we enter a new category because we’ve already seen an opportunity in it. It’s really about how fast we can get to the second product, the third production and so forth.”

From the outside, this new variation of the audio offering appears eerily similar to its predecessor, with one major difference. Where the Zone featured dual ear-cup air purifiers, the OnTrac ditches the concept entirely, going all-in on audio quality. In fact, the Dyson OnTrac headphones are just the second product in the entire lineup to not feature cyclonic technology anywhere, the other being a hair straightener.

For Jake Dyson, much like his famous father, great design isn’t simply an exploration of form and function. It must, as the wall-mounted mantra suggests, solve a problem that others won’t. With OnTrac, the issue hits close to home.

“I’m actually half deaf, so I’ve got a particular interest in audio health,” the chief engineer reveals. “With young children, for example, there’s a certain age where if they are exposed to too high levels of sound, it can damage their ears forever.”

“Our researchers looked at several things, primarily at the speakers themselves and auditory health. Your requirements are very different depending on what time of day and what age you are, and also people’s ears. If you consider all of those things, there’s an awful lot to do in terms of personalisation.”

Hundreds of hours of refinement, research and development reportedly went into the construction of the OnTrac headphones, with Dyson explaining that the audio-first focus represented significant challenges. Where the Zone was a purifier first and headphones second, OnTrac is designed for a premium audio experience. That shift in mindset meant that Dyson’s team of engineers had to completely alter the way they operated, identifying entirely new objectives along the way.

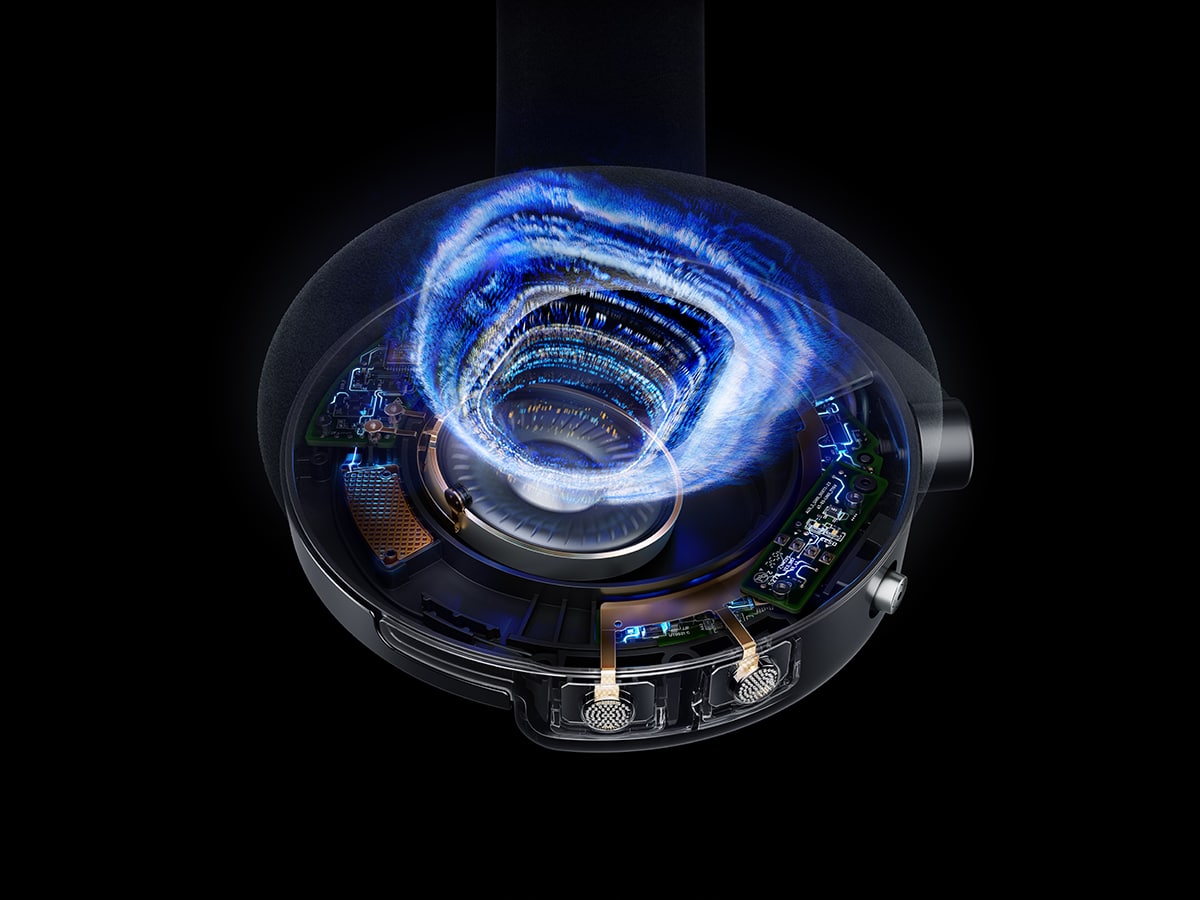

The biggest development for OnTrac is a custom active noise cancellation (ANC) algorithm. Tasked with pushing ANC capabilities to new heights, the integration utilises eight microphones, sampling external sound 384,000 times a second. Dyson explains that this, when combined with the new CNC-milled aluminium material, can cancel up to 40dB of unwanted noise.

“You have to think about the environment, yourself, comfort and what would be interesting to capture with a wearable. A lot of people wear noise-cancelling headphones just for a bit of peace; so you’re in a quiet zone in a noisy environment. Fundamentally, it’s to listen to music. So if you’re going to do anything else with that, it has to be useful as well.”

“It’s a product that we’re proud of as a piece of design. Like the Sony Walkman used to be on your belt; people were really proud of it as a beautiful object. I don’t really see that with other headphones.”

Dyson isn’t kidding, either. While we are used to seeing brands approach consumer technology with a more understated tone, OnTrac leverages vibrancy as a differentiator. The new headphones feature more than 2,000 customisable colour combinations for outer caps and ear cushions. You can simply twist and snap the ear caps off whenever you like, replacing them at will. For a technology company like Dyson, fresh to the world of audio design, it speaks to a renewed ethos. Namely, standing out from the crowd isn’t just a nice-to-have, it’s a necessity.

If you ask Jake Dyson what the most significant aspect of the technology company’s business is, however, the answer may well surprise you. Despite boasting an industry-leading portfolio of innovative products, spanning 84 countries and generating billions in revenue, Dyson’s great legacy is in inspiring a new generation of visionaries.

In 2017, Sir James Dyson founded the Dyson Institute of Engineering and Technology, offering an entirely new form of tertiary education. Here, school leavers study while undertaking a full-time salaried role in Dyson’s engineering team. Undergraduate engineers pay zero tuition fees, work on real-life projects and have no obligation to stay with Dyson once the degree is completed.

It’s a unique formula and one that few companies would dare to try (or have the funds to), but if there is one thing we’ve learned over the years, it is that Dyson isn’t afraid to fail. Trying new things will always lead to learnings and starting new engineers off on a bold new footing is the key to innovation. As Jake Dyson explains, people who think differently, create differently.

“Creative, hardworking, brave people who are not afraid to experiment – those are the sort of attributes we look for, and that’s not only just a designer or an engineer, that’s the business,” he says.

“We want people to think completely differently and not to do what everyone else does, and experiment. Believe that nothing’s possible and not be scared, which is why we enter new categories that other people are leading. We aren’t afraid to go in and play there. We believe that we can make a big difference, and we wouldn’t do it otherwise.”

DISCLAIMER: The author of this post, Nick Hall, was invited to attend Dyson headquarters as a guest of the brand.

Comments

We love hearing from you. or to leave a comment.